System Level Integration with ADS

2

/ SIB - SSDL

System Integration Bench for C919 Cockpit Display System

Overview

To integrate the whole Cockpit Display System of C919 TechSAT has delivered two sets of CDS System Integration Bench, so called SSDL(Sub System Development Lab) to SAVIC, the system supplier of C919 CDS.

For the incremental IV&V approach required by ARP4754A, three levels of integration of CDS has been performed on TechSAT Test & Integration Systems.

MDVS was used to start virtual, model based development (Virtual Integration -> C919 CDS Host Based SW Verification)

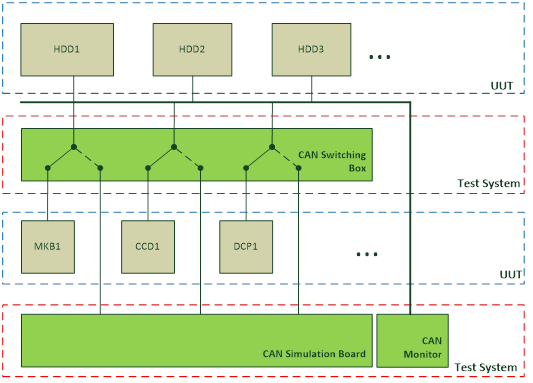

The HDD (Head Down Display) is individually verified using SDIB. (Equipment Level Integration -> C919 CDS HDD Verification)

The SSDL is used for System Level integration and verification.

System Configuration

Software Packages

- ADS2 / Core

-

ADS2 / Toolbox

- ADS2 / SCADE

- ADS2 / TPM

- ADS2 / IOGen

- ADS2 / TFG

- ADS2 / ICDImporter: TechSAT tool for import of OEM ICD format

- A664 TR / TE Test Suite: TechSAT COTS Test Suite for A664 End System Verification

- TechSAT A653 Platform Test Suite: TechSAT COTS Platform Test Suite for A653 platform

Hardware Packages

-

5x ADS2 19 Inch Racks with

-

-

Realtime High-End PC for ADS2 SW modules and Simulations

-

I/O Devices for stimulation and monitoring of all CDS equipment

-

A818 analyzer

-

UUT power (28VDC, 115VAC)

-

IMA Power

-

Signal Breakout Unit

-

Test Unit Adapter for AFDX switches, IMA Cabinets, RDIUs

-

Wiring Matrix

-

Application Logical Architecture

Logical Architecture Overview

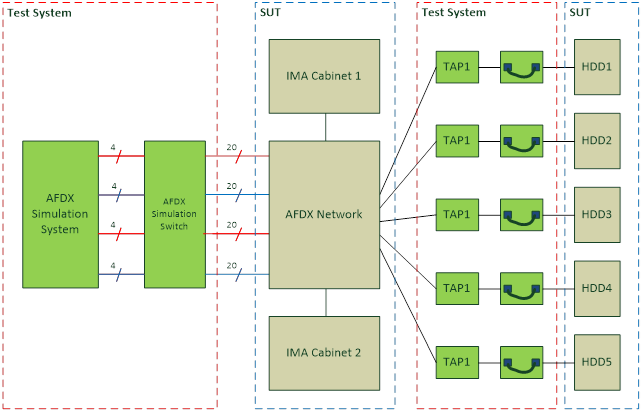

A664 Simulation & Monitoring Schematics

A825 Simulation & Monitoring Schematic

Use Cases

The purpose of SSDL is to support the integration and verification of whole C919 Cockpit Display System.

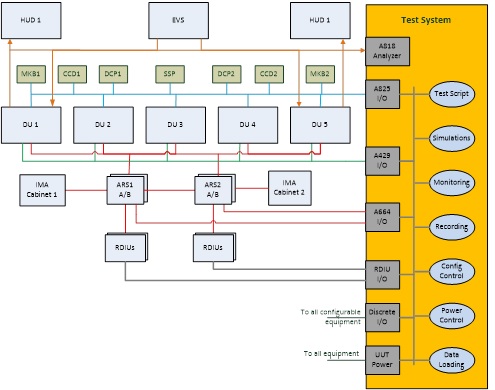

The SSDL consist of the CDS Equipment installed and interconnected in a representative way for the aircraft installation and a Test System that simulates all other aircraft systems communicating with the CDS.

CDS Equipment installed on the SSDL includes:

- ll HDD Units

- Provisions for later addition of HUD and EVS

- All Control Panels (MKB, CCD, DCP, SSP/RCP, RLS)

- ISIS

- External A664 Switches

- IMA Cabinets with internal A664 Switches and all GPMs executing CDS relevant applications.

- RDIUs with CDS relevant gateway and I/O functions.

The SSDL provides:

- All I/O resources to simulate the environment of the CDS

- I/O resources to monitor internal bus traffic between CDS equipment

- Power Supply for all aircraft equipment installed in the bench

- Discrete outputs for pin configuration of all equipment.

- Simulations of all aircraft systems communicating with the CDS.

- Data Monitoring, Recording, Replay

- Automatic and manual testing

Final System Integration and verification of complete CDS

To integrate and verify the whole CDS system, the SSDL is operated in Fully Representative Configuration Mode.

In this mode, all IMA resources are installed as in the aircraft.

The SSDL is setup to simulate specific scenarios for the different functions of CDS. The test engineer/pilot interacts with the cockpit though the display system controls and verify correct behavior.

Perform CDS formal verification against T3 / T4 requirements

For this purpose, the SSDL is operated in Multi-Display Configuration Mode.

In this mode, no RDIU and no real A644 Switches are used. The RDIUs and A664 switch are either not installed or if installed, they are disabled through patch panels and corresponding switches.

This mode is also used for Software verification at T4 level where the functionality can not be verified on SDIB.

Perform CDS certification tests as defined by CDS Certification Plan

All MOC4 tests defined by CDS certification Plan are performed on SSDL.

The traceability from system requirements to test results is supported through SW tools provided and configured by TechSAT.